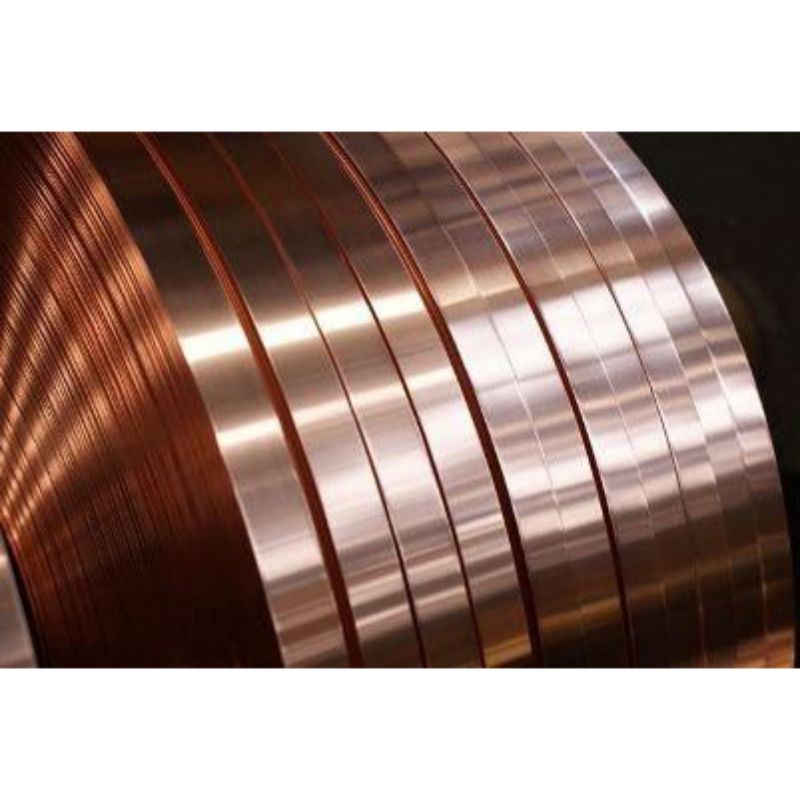

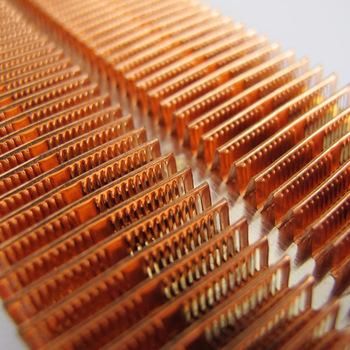

C14415 copper foil strip, also known as CuSn0.15, is a specific type of copper alloy strip used in various applications. The advantages of C14415 copper strip make it a versatile material for various electrical and mechanical applications that require high conductivity, good machinability, thermal conductivity, strength, and corrosion resistance.

Chemical Composition

|

UNS:C14415

(JIS:C1441 EN:CuSn0.15)

|

Cu+Ag+Sn

|

Sn

|

|

99.95 min.

|

0.10~0.15

|

Mechanical Properties

|

Temper

|

Tensile strength

Rm

MPa (N/mm2)

|

Hardness

(HV1)

|

|

GB

|

ASTM

|

JIS

|

|

H06(Ultrahard)

|

H04

|

H

|

350~420

|

100~130

|

|

H08(Elasticity)

|

H06

|

EH

|

380~480

|

110~140

|

| Notes: The technical data in this table is recommended. Products with other properties can be provided according to customers’ requirements. 1)only for reference. |

Physical Properties

| Density, g/cm3 |

8.93 |

| Electrical conductivity (20℃), %IACS |

88(annealed) |

| Thermal conductivity (20℃), W/(m·℃) |

350 |

| Coefficient of thermal expansion (20-300℃), 10-6/℃ |

18 |

| Specific heat capacity (20℃), J/(g·℃) |

0.385 |

Thickness and Width Tolerances mm

|

Thickness Tolerance

|

Width Tolerance

|

|

Thickness

|

Tolerance

|

Width

|

Tolerance

|

|

0.03~0.05

|

±0.003

|

12~200

|

±0.08

|

|

>0.05~0.10

|

±0.005

|

|

>0.10~0.18

|

±0.008

|

|

Notes: After consultation, products with higher precision requirements can be provided.

|